Construction & plastics processing

We offer variegated solutions for processing plastics with CAE and CAD-methods. From new plannings to the point to improvements of existing constructions we elaborate engingeering drawings and data.

Milling technology

We are primarily specialised in manufacturing components with a dimension up to L: 2400 x W: 1200mm, material thickness up to 150mm. Here we use the Biesse Skill GFT 1224 with vacuum clamp table.

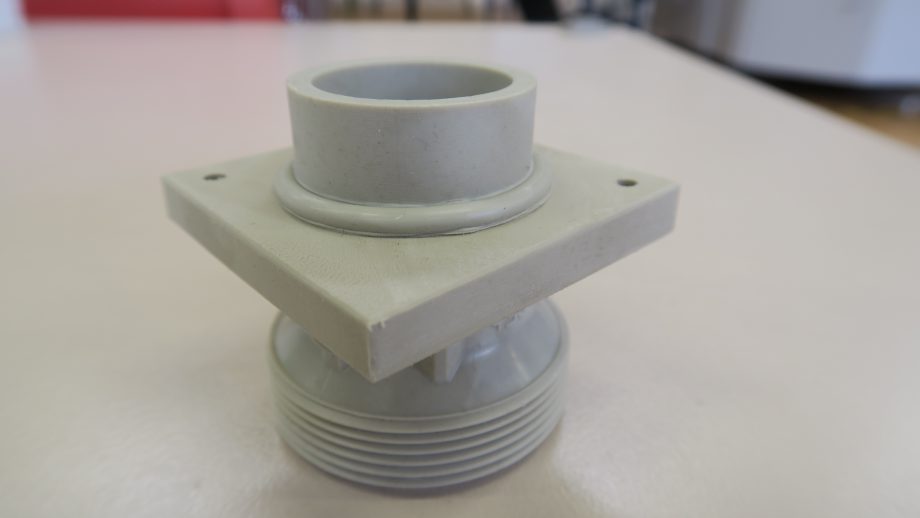

Turning technology

We elaborate component parts consisting of solid, pipes and further elements according to costumised requirements.

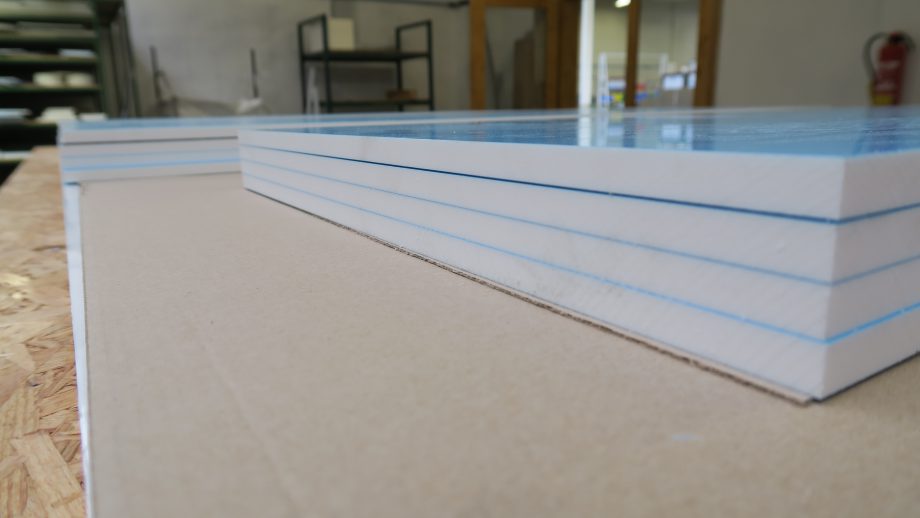

Material

To efficient work off incoming orders there are always semi-finished products available in stock. We primarily process technical plastics like PP, PVC, PMMA, POM, PE, PTFE, PEEK, PVDF and PA 6/7, 6/12. On request we also work with other materials. Furthermore we offer the processing of aluminium and brass.

Welding technology

Since the foundation of the company we edit welded constructions made of polypropylene. In the sector of weld constructions we offer a large range of attainments from simple joining semi-finished products to the point of aggregate constructions and apparatus engineering. At this juncture we use high-grade polypropylene plastics from well-known german producers.

Adhesive technology

As well in our range are a huge selection of adhesive plastics, which we process custom-built and with customer’s specifications. Especially we use PVC and PMMA plastics. Other adhesive raw materials on request.